|

|

|

|

PRODUCTS

|

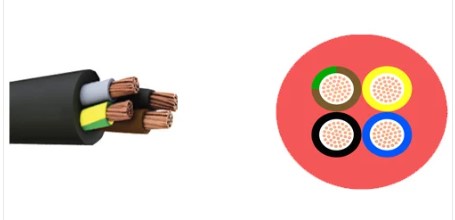

What you need to know about rubber cable? Rubber has been used as insulation and sheathing material for cables long before other insulation materials, such as PVC and PE, came into everyday use. Rubber cables continues to be widely used in domestic and industrial applications. Initially, natural rubber was used, but now it has been largely replaced by various synthetic rubbers. All rubber is heat-treated or crosslinked by a process called vulcanization. It is a thermosetting material that will not soften or melt when exposed to heat. Adding various additives such as fillers, vulcanizing agents, accelerators, antioxidants, and antiozonants significantly alters the properties of these base rubbers. Rubber cables are flexible wires used to connect equipment under moderate and severe operating conditions. Rubber cables Chennai includes several custom models of rubber wire for special applications with increased mechanical stresses. What are the advantages of using a rubber-insulated cable?

The main advantage of all-rubber cables over other insulated cables is their greater flexibility over a temperature range. It also has excellent water absorption. Rubber insulated cable also have excellent abrasion and weather resistance, making them particularly suitable in harsh environments as routing leads for portable electrical equipment, power tools, pumps, and generators. It also features rubber cables and has excellent oil and chemical resistance. Rubber cable- Consideration Electrical companies use rubber-insulated cables for power generation and transmission. In addition to long service life under normal conditions in nuclear and conventional power plants, safety considerations are essential for this electrical equipment. Common rubber cable compounds include natural rubber, SBR or styrene-butadiene rubber, butyl, EPR or ethylene-propylene rubber, silicone, polychloroprene, chlorosulfonated polyethylene (PCP), and fluorocarbons. You can connect equipment in mild, average, and harsh operating conditions using rubber cables as flexible cables. Power Cable Corporation specialize in rubber wires primarily for application areas where mechanical stresses can be high to very high. What you need to know about rubber cable? Rubber has been used as insulation and sheathing material for cables long before other insulation materials, such as PVC and PE, came into everyday use. Rubber cables continues to be widely used in domestic and industrial Initially, natural rubber was used, but now it has been largely replaced by various synthetic rubbers. All rubber is heat-treated or crosslinked by a process called vulcanization. It is a thermosetting material that will not soften or melt when exposed to heat. Adding various additives such as fillers, vulcanizing agents, accelerators, antioxidants, and antiozonants significantly alters the properties of these base rubbers. Rubber cables are flexible wires used to connect equipment under moderate and severe operating conditions. Rubber cables Chennai includes several custom models of rubber wire for special applications with increased mechanical stresses. What are the advantages of using a rubber-insulated cable?

The main advantage of all-rubber cables over other insulated cables is their greater flexibility over a temperature range. It also has excellent water absorption. Rubber insulated cable also have excellent abrasion and weather resistance, making them particularly suitable in harsh environments as routing leads for portable electrical equipment, power tools, pumps, and generators. It also features rubber cables and has excellent oil and chemical resistance. Rubber cable- Consideration Electrical companies use rubber-insulated cables for power generation and transmission. In addition to long service life under normal conditions in nuclear and conventional power plants, safety considerations are essential for this electrical equipment. Common rubber cable compounds include natural rubber, SBR or styrene-butadiene rubber, butyl, EPR or ethylene-propylene rubber, silicone, polychloroprene, chlorosulfonated polyethylene (PCP), and fluorocarbons. You can connect equipment in mild, average, and harsh operating conditions using rubber cables as flexible cables. Power Cable Corporation specialize in rubber wires primarily for application areas where mechanical stresses can be high to very high. |

|

applications.

applications.